Ukumisa kwangaphambili: Ukuzalisa i-Pump Casing

Ngaphambi kokuba aimpompo ye-centrifugal yenqanaba elinyeiqalisiwe, kubalulekile ukuba isingxobo sempompo sizaliswe ngolwelo olulungiselelwe ukuthuthwa. Eli nyathelo libalulekile kuba impompo yamanzi ye-centrifugal ayikwazi ukuvelisa ukufunxa okuyimfuneko ukutsala ulwelo kwimpompo ukuba i-casing ayinanto okanye izaliswe ngumoya. Ukuqala kwinqanaba elinye lempompo ye-centrifugal, okanye ukuyigcwalisa ngolwelo, iqinisekisa ukuba inkqubo ilungele ukusebenza. Ngaphandle koku, umpompo wamanzi we-centrifugal awuyi kukwazi ukudala ukuhamba okufunekayo, kwaye i-impeller ingonakaliswa yi-cavitation-into eyenzekayo apho i-vapor bubbles ifom kwaye iwele ngaphakathi kwe-liquid, enokubangela ukugqoka okubalulekileyo kumacandelo epompo.

Umfanekiso| Ubunyulu Single Stage Centrifugal Pump PSM

Indima ye-Impeller kwi-Fluid Movement

Emva kokuba ipompo enye ye-centrifugal ifakwe ngokufanelekileyo, umsebenzi uqala xa i-impeller-inxalenye ejikelezayo ngaphakathi kwempompo-iqala ukujikeleza. I-impeller iqhutywa yi-motor kwi-shaft, ibangela ukuba ijikeleze ngesantya esiphezulu. Njengoko i-impeller blades ijikeleza, ulwelo oluvaleleke phakathi kwabo nalo luyanyanzeleka ukuba lujikelezise. Le ntshukumo inika amandla e-centrifugal kulwelo, eyona nkalo ingundoqo yokusebenza kompompo.

I-Centrifugal force ityhala ulwelo ukusuka kumbindi we-impeller (eyaziwa ngokuba liliso) ukuya kumphetho ongaphandle okanye iperiphery. Njengoko ulwelo luqhutyelwa ngaphandle, lufumana amandla ekinetic. La mandla ngawona enza ukuba ulwelo luhambe ngesantya esiphezulu ukusuka kungqameko lwangaphandle lwe-impeller ukuya kwivolute yempompo, igumbi elimilise okwe spiral elijikeleze i-impeller.

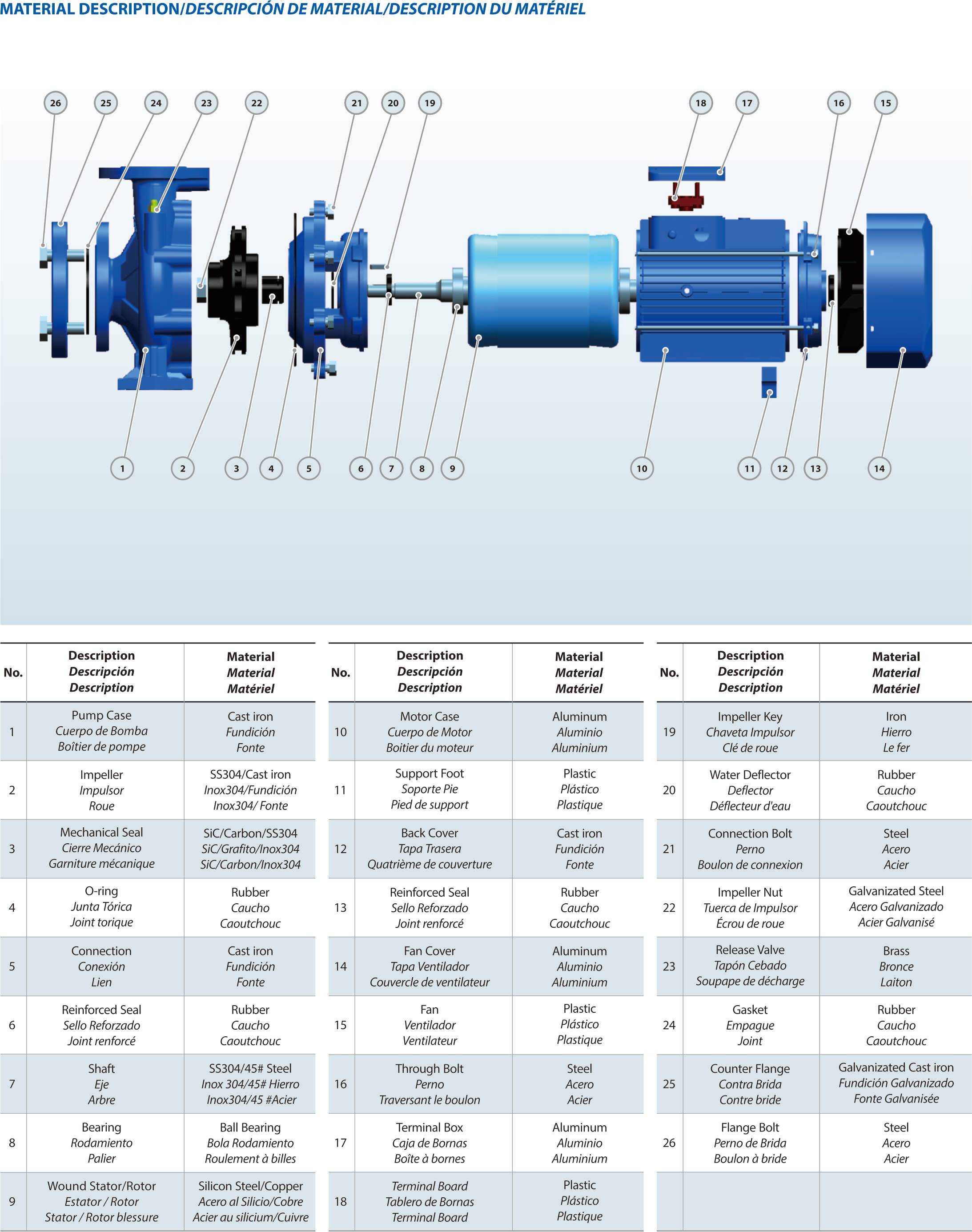

Umfanekiso| Ubunyulu beSigaba esinye seCentrifugal Pump PSM Components

Ukuguqulwa kwamandla: ukusuka kwiKinetic ukuya kuxinzelelo

Njengoko i-speed-speed liquid ingena kwi-volute, isantya saso siqala ukuhla ngenxa yokwandiswa kwemilo yegumbi. Ivolonti yenzelwe ukucothisa ulwelo ngokuthe ngcembe, nto leyo ekhokelela kuguquko lwamandla ekinetic abe ngamandla oxinzelelo. Oku kunyuka koxinzelelo kubaluleke kakhulu kuba kuvumela ukuba ulwelo lukhutshwe kwimpompo kuxinzelelo oluphezulu kunokuba lungene, okwenza kube lula ukuthutha ulwelo ngokusebenzisa imibhobho yokukhupha ukuya kwindawo ekujoliswe kuyo.

Le nkqubo yokuguqulwa kwamandla sesinye sezizathu eziphambili zokuba kutheniiimpompo zamanzi ze-centrifugalzisebenza kakuhle kakhulu ekuhambiseni ulwelo kumgama omde okanye kwiindawo eziphakamileyo. Ukuguqulwa okugudileyo kwamandla e-kinetic kuxinzelelo luqinisekisa ukuba impompo yamanzi ye-centrifugal isebenza ngokufanelekileyo, ukunciphisa ilahleko yamandla kunye nokunciphisa iindleko zokusebenza zizonke.

Ukusebenza ngokuqhubekayo: Ukubaluleka kokuGcina ukuHamba

Inkalo ekhethekileyo yeempompo zamanzi ze-centrifugal kukukwazi kwabo ukudala ukuhamba okuqhubekayo kolwelo ukuba nje i-impeller ijikeleza. Njengoko ulwelo luphonswa ngaphandle ukusuka kumbindi we-impeller, indawo yoxinzelelo oluphantsi okanye i-vacuum encinci yenziwa kwiso le-impeller. Le vacuum ibalulekile kuba itsala ulwelo oluninzi kwimpompo ukusuka kumthombo wonikezelo, igcina ukuhamba okuqhubekayo.

Uxinzelelo oluhlukileyo phakathi komphezulu wolwelo kwitanki yomthombo kunye nommandla woxinzelelo oluphantsi kwiziko le-impeller uqhuba ulwelo kwimpompo. Logama nje lo mahluko woxinzelelo ukhona kwaye i-impeller iyaqhubeka nokujikeleza, inqanaba elinye lempompo ye-centrifugal iya kuhlala itsala kwaye ikhuphe ulwelo, iqinisekisa ukuhamba okuzinzileyo nokuthembekileyo.

Isitshixo sokuSebenza ngokufanelekileyo: Ukugcinwa ngokufanelekileyo kunye nokusebenza

Ukuqinisekisa ukuba impompo ye-centrifugal yesigaba esisodwa isebenza ngokufanelekileyo, kubalulekile ukulandela iindlela ezifanelekileyo ekusebenzeni nasekugcinweni. Ukujonga rhoqo inkqubo yempompo yempompo, ukuqinisekisa ukuba i-impeller kunye ne-volute ayinayo i-debris, kwaye ukubeka esweni ukusebenza kwemoto ngamanyathelo ayimfuneko ekugcineni impompo yokusebenza kakuhle kunye nokuphila ixesha elide.

Ukulinganisa ngokufanelekileyo impompo kwisicelo esicetywayo nako kubalulekile. Ukulayisha ngaphezulu impompo ngokuyicela ukuba ihambise ulwelo olungaphezulu kunoko beluyilelwe kunokukhokelela ekunxityweni okugqithisileyo, kuncitshiswe ukusebenza kakuhle, kwaye ekugqibeleni, ukusilela komatshini. Kwelinye icala, ukulayisha phantsi kwenqanaba elinye impompo ye-centrifugal kunokubangela ukuba isebenze ngokungafanelekanga, okukhokelela ekusebenziseni amandla ngokungeyomfuneko.

Ixesha lokuposa: Aug-15-2024