Do uyazi? Ama-50% onyaka ewonke amandla okwenziwa kwempompo yelizwe asetyenziselwa ukusetyenziswa kwempompo, kodwa umyinge wokusebenza kakuhle kwempompo ungaphantsi kwama-75%, ngoko ke i-15% yokuveliswa kwamandla ngonyaka ichithwa yimpompo. Ingatshintshwa njani impompo yamanzi ukonga amandla ukunciphisa ukusetyenziswa kwamandla? Ukusetyenziswa, ukukhuthaza ukonga kunye nokunciphisa ukukhutshwa kwe-emission?

01 Ukuphucula ukusebenza kakuhle kweemoto

Phuhlisa iimotor ezonga amandla, ukunciphisa ilahleko ngokuphucula izixhobo ze-stator, sebenzisa iikhoyili zobhedu ezisulungekileyo ezikumgangatho ophezulu, uphucule iinkqubo zokujija, kunye nokuphucula ukusebenza kakuhle; yenza umsebenzi olungileyo wokukhetha imodeli phambi kokuthengisa, ekwaluncedo olukhulu ekuphuculeni ukusebenza kakuhle kweenjini.

02 Ukuphucula ukusebenza kakuhle koomatshini

Ukuphucula inkqubo yokuthwala kunye nokusebenzisa iibheringi kunye nokugxila okulungileyo ukunciphisa ilahleko yokuthwala; ukwenza ipolishi, ukugquma, kunye nonyango olungagungqiyo lweendawo zokuhamba kwamanzi ukunciphisa umonakalo obangelwa ziimpembelelo ezifana ne-cavitation kunye ne-friction, kunye nokuphucula ukusebenza kwempompo Kukwandisa ubomi benkonzo yamacandelo. Eyona nto ibaluleke kakhulu kukwenza umsebenzi omhle ekulawuleni umgangatho ngexesha lokucubungula iinxalenye kunye nokuhlanganisana, ukwenzela ukuba ipompo ikwazi ukufikelela kwimeko engcono yokusebenza, enokunciphisa ukusetyenziswa kwamandla kunye nokuphucula ukusebenza kakuhle.

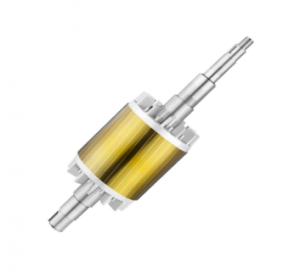

Umfanekiso | I-shaft yensimbi engenasici

03 Phucula ukubaleka kwembaleki

Xa kusetyenzwa kunye nokudibanisa i-impeller kunye nenxalenye yokuhamba kwe-blade passage, i-rust, i-scale, i-burr kunye ne-flash iphuculwe ukunciphisa ukungqubuzana kunye nokulahleka kwe-vortex phakathi kwamanzi kunye nodonga lokuhamba. Inokuthi igxininise kwiindawo eziphambili ezichaphazela ukusebenza kakuhle, njenge: i-vane yesikhokelo esilungileyo, i-inlet ye-inlet ye-impeller, i-outlet inxalenye ye-impeller, njl. Kufuneka kuphela ukuba iphuculwe ukuze ibone i-metallic luster, kwaye kwangaxeshanye, ukuphambuka kwe-scoop ye-impeller akugqithisi ixabiso elichaziweyo lokunciphisa ukulahleka kwe-friction ye-disc.

Umfanekiso | impompo yomzimba

04 Ukuphucula ukusebenza kakuhle kwevolumetric

Ukulahleka komthamo wempompo yamanzi kubonakaliswa ikakhulu kwilahleko yamanzi kwisithuba seringi yokutywina. Ukuba indawo edibeneyo yendandatho yokutywina ifakwe ngentsimbi yensimbi kwaye "0" i-rubber yokutywinwa ifakwe i-rubber, umphumo wokutywinwa unokuphuculwa kakhulu, kwaye ubomi benkonzo yohlobo olufanayo lokutywina luphuculwe kakhulu, olunokuphucula ukusebenza kakuhle kwempompo yamanzi kunye nokunciphisa iindleko zokugcinwa. Umphumo uyamangalisa.

Umfanekiso | O umsesane wokukhetha

05 Ukuphucula ukusebenza kakuhle kolwelo lwamanzi

Ukulahleka kwe-hydraulic yempompo kubangelwa yimpembelelo yokuhamba kwamanzi ngomjelo wempompo kunye nokukhuhla kunye nodonga lokuhamba. Indlela ephambili yokuphucula ukusebenza kakuhle kwe-hydraulic yempompo kukukhetha indawo efanelekileyo yokusebenza, ukuphucula ukusebenza kwe-anti-cavitation kunye nokusebenza kwe-anti-abrasion yempompo, kunye nokunciphisa ubunzima obupheleleyo bomphezulu weendawo ezidlulayo. Ukunciphisa uburhabaxa kunokufezekiswa ngokufaka i-lubricious coating kwiitshaneli zempompo.

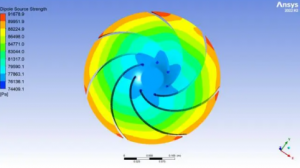

Umfanekiso | Ukulinganisa kwe-hydraulic ye-CFD

06 Fuhlengahlengiso lokuguqulwa kwesicelo

Umsebenzi wokuguqulwa kwesantya sokuguqulwa kwesantya sompompo wamanzi kuthetha ukuba umpompo wamanzi uqhuba phantsi komqhubi we-motor speed adjustable, kwaye indawo yokusebenza yesixhobo sepompo yamanzi iguqulwa ngokuguqula isantya. Oku kwandisa kakhulu uluhlu olusebenzayo lwempompo yamanzi, eyona ndlela ibaluleke kakhulu kwaye isebenzayo yokulungelelanisa kubunjineli. Ukuguqula i-motor non-speed-regulating motor kwi-speed-regulating motor, ukwenzela ukuba ukusetyenziswa kwamandla kuyahluka kunye nomthwalo, kunokugcina amandla amaninzi.

Umfanekiso | Impompo yombhobho woguqulo rhoqo

Ezi zingentla zezinye iindlela zokugcina amandla kwiimpompo. Thanda kwaye ubeke ingqaleloUbunyuluIshishini lempompo ukuze ufunde ngakumbi malunga neempompo.

Ixesha lokuposa: Aug-28-2023